Jet Tenders

Since 1962 forerunners, always

As specialists in water jet propulsion systems for over 50 years, Castoldi knows what it takes to design and manufacture the perfect hulls which allow Castoldi waterjet drives full scope for enhancing their great benefits.

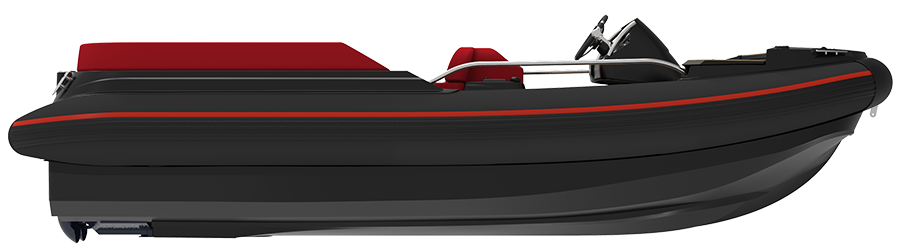

In its own boatyard Castoldi carries out full manufacturing of the Jet Tenders, from developing and testing hull forms, to quality control checks during every productive process, all trough the use of state of the art materials Jet Tenders consist of a range of rigid inflatable boats fitted with diesel engines, water jet drives and the highest quality equipment available for best performing yacht tender duties.

Features include reduced weight and height (through electrically controlled, retractable helm or console), self bailing cockpit even at standstill (except JT 14, JT15 and JT16), a deck configuration walk-through from transom to bow, hulls specially designed for the waterjet drive propulsion, a disconnecting clutch (integrated into the jet unit) for a true boat holding position.

Jet Tenders can all travel, remaining stable and dry, at more than 30 knots in rough offshore waters, as well as in shallow waters. They can land on the beach and cross at speed sand and mud banks. Jet Tenders do not have any exposed rotating parts or protrusions under the keel and are therefore safe for people in the water or on-board and able to safely cruise at night.

Manoeuvrability is superb. Jet Tenders manoeuvre better and faster than boats with traditional propulsion systems in closed spaces as they can use maximum power (and, therefore, maximum thrust) even at low speeds. They are capable of turning on their own axes and of stopping within a maximum space of 1,5-2 times their own length, to avoid impacts and collisions.